Prototypes for Production

When working with a product, I noticed a point of weakness within the mounting system. I had concerns that the supporting clips were not strong enough to hold the fixture in place and weren't meeting internal specifications. After qualitative analyses, including load and pull-force tests, I determined that there was room for improvement.

TOOL SAFE

MODIFICATIONS

I began by looking for simple, tool-safe modifications to implement that would be cost-effective and still increase the overall strength of our clips. I reached out to our manufacturer for the tool CAD files in order to better understand the injection molding process.

I worked with the manufacturing team to remove excess material from the design, then ordered new production-grade prototypes from an international vendor. I tested them side-by-side with the current design to ensure improvement to the product robustness.

NEW-TWO PART DESIGN

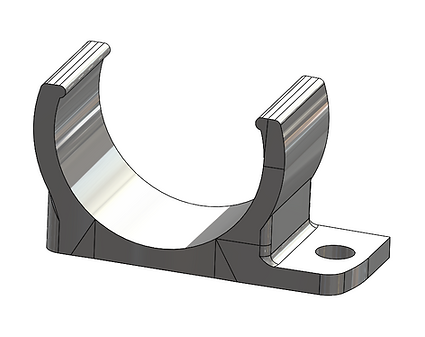

In addition to a quick, tool-safe update, I decided to pursue some more out-of-the-box ideas. I came up with a two-part solution, in which one part would rotate within the other.

I mocked up several ideas in SolidWorks and 3D printed prototype versions for testing. While they proved to be robust, the cost was definitely a concern when looking into mass manufacturing as each part would require a separate tool.

Mechanical Engineer

PAX is an electronic vaporizer company that creates next-generation consumer devices while supporting social justice, access, and equity in the industry. As a full-time engineer, I've been involved in various stages of the product design process including early-stage development, design for manufacturing, and validation testing. My project work has not only improved my technical skills but has introduced me to the importance of global supply chain and manufacturing.

Associate Mechanical Engineer

Continuum is a global innovation design firm that develops products, services, and experiences to improve people’s lives. My final co-op placement allowed me to work across the Mechanical and Electrical Engineering teams on several contracted projects, focusing on manufacturing development and validation. Due to the COVID-19 pandemic and government-mandated work-from-home order, the scope of my co-op was ultimately limited.

Mechanical Engineering

R&D Co-op

Haemonetics Corporation is a global leader in blood management solutions, producing a wide variety of devices and consumables primarily focused on blood processing systems and plasma collection. My first co-op placement allowed me to work towards product development across the mechanical, electrical and systems engineering teams as well as gain exposure to advanced laboratory procedures and nano-dispensing technologies.