Rapid Prototyping

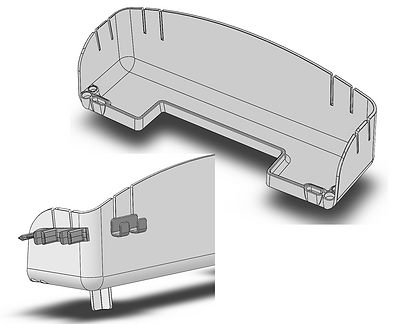

The process of collecting plasma requires the use of needles, tape, test tubes, and other disposable items. Many clients struggled to juggle all of these items while performing a simple procedure. This project directly addressed those concerns by implementing a configurable tray and interchangeable parts to accommodate disposable items, freeing up the hands of the user.

FINAL

After receiving feedback from clients, the design of each part was adjusted for manufacturing, considering injection molding and feasibility. At the end of my co-op, the latest tray design was sent out for final adjustments and the model was approved for an initial release of 25,000 parts.

PLANNING

The idea for a tray was suggested by several customers, however, each customer used different items and therefore wanted different features on a tray. This lead to the idea of slots to allow for the addition of configurable parts.

MODIFICATIONS

The tray and each of the configurable parts were modeled in SolidWorks and 3D printed to confirm fit, functionality, and ease of use. Each part underwent several iterations as they were reviewed and tested by myself, the ME team, and the clients themselves.

Mechanical Engineer

PAX is an electronic vaporizer company that creates next-generation consumer devices while supporting social justice, access, and equity in the industry. As a full-time engineer, I've been involved in various stages of the product design process including early-stage development, design for manufacturing, and validation testing. My project work has not only improved my technical skills but has introduced me to the importance of global supply chain and manufacturing.

Associate Mechanical Engineer

Continuum is a global innovation design firm that develops products, services, and experiences to improve people’s lives. My final co-op placement allowed me to work across the Mechanical and Electrical Engineering teams on several contracted projects, focusing on manufacturing development and validation. Due to the COVID-19 pandemic and government-mandated work-from-home order, the scope of my co-op was ultimately limited.

Mechanical Engineering Co-op

Ecosense Lighting is a start-up company focused on creating new technologies to change the way that the world views light. My second co-op placement allowed me to be a part of a fast-paced product development team, supporting existing products through feature additions, validation testing, and root-cause analysis. Furthermore, I got the opportunity to work on custom and next-generation products, designing for prototyping and manufacturing.